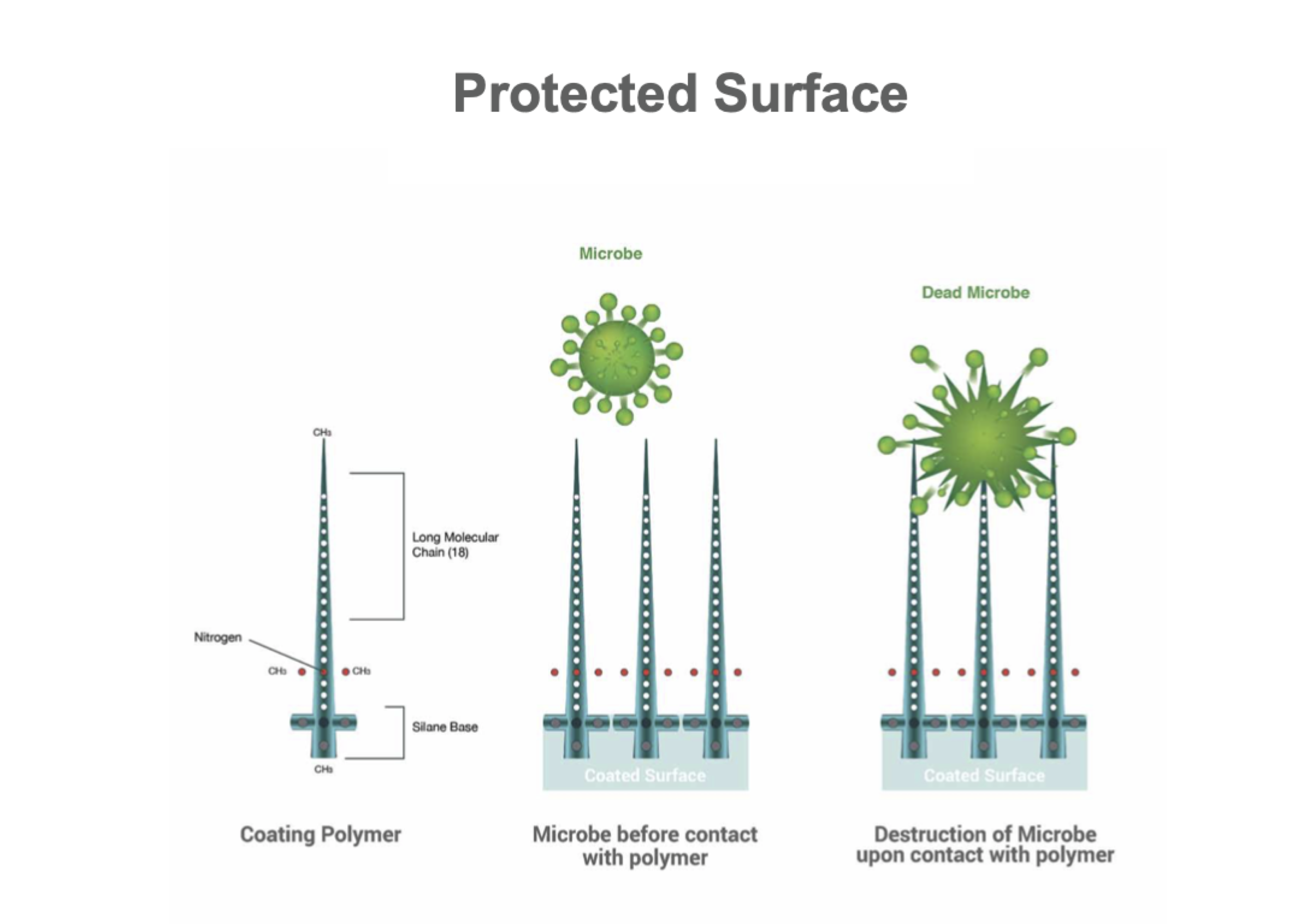

Antimcribial Coatings technology is based on the use of quaternary ammonium silicone compounds (“SiQAC”) as antimicrobial agents, either in solvent, or in aqueous and stable solutions.

Making these compounds using a water-based system provides a host of benefits. They are non-flammable and require no solvents for dilution. They require no special handling, are uniformly dispersible on almost any surface, and are simple and economical to use because of their extended shelf-life.

When the ammonium salts react with certain organosilanes they form an integrated system. Once this system is applied to any surface, it forms an invisible (one molecule deep) and durable (through ion exchange and rapid polymerization) antimicrobial protection.

THE BENEFITS OF ANTIMICROBIAL COATINGS

This process and protection give people peace of mind. Utilization of this technology creates a healthier environment for you, your patients, clients, and patrons, without the use of harmful chemicals. Treatment of porous and non-porous surfaces will inhibit germs, viruses, and odour-causing bacterias from plaguing your facility with germs and odours. This shows you care and can lead to more business! Not only does it appeal to your customers, but it benefits your business as well. Fewer pathogens mean few sick days for employees, so your business and team will be operating at its best more often!

Continual Sanitization

The coating doesn’t just terminate existing germs on a treated surface, it actively protects against their existence for a long period of time.

Prevents Microbe Resistance

Bacteria can become resistant to chemical cleaning products but Nordic Chem’s “nanospike” technology inhibits germs from living and growing on a surface, reducing the chance for them to adapt and mutate.

Optimal Efficacy

Protects against a vast range of viruses, bacterias, and pathogens. Our coatings are water-based, simple and effective..

Easy to Apply

Our products are designed with our customers in mind. While we always recommend a professional installation, Nordic Chem can also be applied via a spray bottle or fogging system.

Surface Adaptability

Nordic Chem’s active ingredient has been tested and proven to work on a number of porous and non-porous surfaces in a variety of environments. The bond formed provides durable surface protection that withstands even routine cleaning.

ENVIRONMENTAL AND ANTIMICROBIAL COATINGS

This new generation of antimicrobial coatings are water-based.

The coatings contain no VOC, heavy metals, formaldehyde treatment, phenol groups, or odour-causing agents that can lead to allergies or asthma.

Q: As a business owner, why should I apply this product to my premises?

A: By combining Antimicrobial coating with regular cleaning and disinfecting, a premise can be sure it is implementing the highest standard of surface defence against harmful microbes.

Q: My business is closed at the moment due to Covid-19. Should I apply this product before my premises reopens or after?

A: We strongly recommend applying Antimicrobial before your business reopens. This will provide the applicator with a clean and empty space for the application. Applying the coating before people potentially bring in contamination is a sensible action plan.

Q: Does the product terminate enveloped viruses?

A: Yes, it is effective against this type of virus as the coating terminates by puncturing the cell wall and rendering the virus unable to infect. Studies have been shown to prove this and are available to view on request.

Q: Have there been tests done?

A: Yes, there are several tests done on the active ingredients by independent laboratories. We can provide these on request.

Q: How long does your coating last?

A: Our antimicrobial coating will be fully functional for 90 days.

Q: How is your coating removed?

A: Our coating will not be removed by normal cleaning or disinfectants, it can only be removed with abrasion.

Q: What does antimicrobial coating protect against?

A: Our coating protects your surfaces from a range of viruses, bacterias, mold, algaes and odors. Also, the coating acts as a sacrificial layer of protection for the surface itself, protecting against micro-scratches and general wear and tear.

Q: Is your antimicrobial coating a chemical kill process?

A: No, the technology that our coating uses is a mechanical kill, creating a very thin layer of “nano-spikes” that penetrate the virus/bacteria that comes in contact with the coating, destroying the cell.

Q: Once it has adhered to the surface, does it leach any chemicals into the environment?

A: No, once Antimicrobial coating has bonded to the surface it creates a durable layer of protection which provides an inhospitable environment for pathogens, by mechanical means, and the coating does not leach any chemicals into the environment.

Q: What is the difference between Antimicrobial coating and a standard disinfectant?

A: The major difference is this product does not evaporate after being applied, the coating bonds to the surface it has been applied to for 90 days.

Q: Are there other long term coating solutions for eliminating bacterias and viruses?

A: The only other technology that is currently available for long term surface protection are coatings that are terminating the pathogens by infecting the microorganism with a chemical agent such as silver, copper or zinc. We have chosen to utilize its technology as it is highly effective without leaching chemicals into the environment once the coating has cured.

Q: What can your coating be applied to?

A: Our coating will adhere to a wide variety of surfaces including metals, plastics, ceramic, carpet, timber, and upholstery. Antimicrobial is colourless and odourless by nature, therefore it does not stain fabric materials.

Q: Does your coating leave a residue behind?

A: No, our antimicrobial coating provides its users with an invisible shield of protection that is undetectable to the naked eye.

Q: Is this a replacement to regular cleaning and disinfecting?

A: No, this is an additional level of protection that does not only eliminate harmful microorganisms on application but continues to eliminate them all day every day.

Q: How long does it take for the coating to cure?

A: After a few minutes the coating will be dry to the touch, however, we recommend you allow it 2 hours for the coating to completely bond to the surface it has been applied to.

Q: Is the product approved for use in the EU?

A: Yes, we have ensured to be registered in the majority of the European countries and are following the guidelines set out by ECHA (European Chemicals Agency).

Q: What is the recommended application method?

A: We use electrostatic fogging to apply the coating to ensure all surfaces have an even/complete layer of protection.